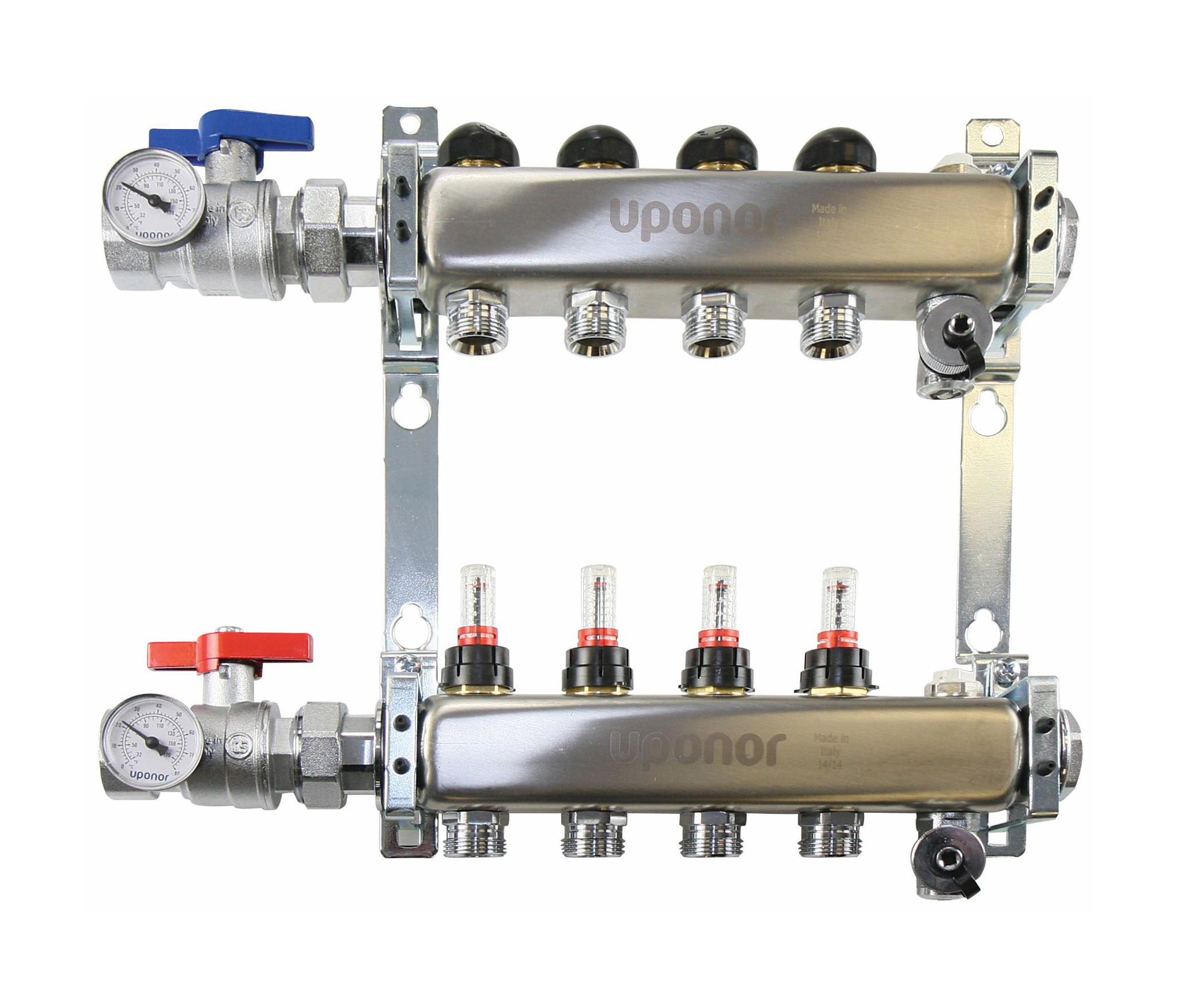

The Stainless-steel Manifold Assembly with flow meter comes fully assembled and ready for installation. Use the included flow meters located on the supply manifold to balance the loops across the manifold. The return manifold comes equipped with isolation valves for easy loop isolation. For multiple zoning on the manifold, the black caps are removed and replaced with Uponor Thermal Actuators. The manifold body ends have R32 union connections and the loop outlets have R20 male threads. The included manifold supply and return ball valves come with an R32 x 1" NPT connection.

Features:

- 1" and 1-1/4" manifold offering

- Competitively priced metal alternative

- Corrosion-resistant, stainless-steel barrel

- NPT-threaded ball valve for easy, cost-effective transition

- Balancing and isolation valves for complete loop isolation

- Compatible with all glycols used in radiant heating and cooling systems

- Integrated, full-port ball valves with temperature gauges

- Integrated flow meters for simple system balancing

- Temperature/Pressure ratings:

- 68°F (20°C) at 145 psi

- 158°F (70°C) at 87.4 psi

- 194°F (90°C) at 43.8 psi

- Pre-assembled and ready to install right out of the box